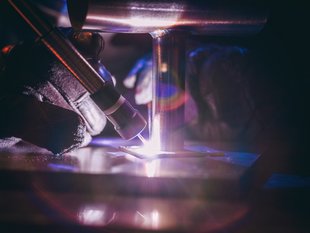

Welding

Welding of the highest quality

Our qualified and certified welders have full command over the welding process – TIG, electrode welding, MIG/MAG and flux-cored wire.

We weld mainly:

- Unalloyed and low-alloy steels, such as: S/E/P 235 – 355

- Stainless, duplex and heat-resistant steels, such as: 1.4301, 1.4306, 1.4307, 1.4404, 1.4435, 1.4571, 1.4462, 1.4821

- Special alloys, such as: 2.4602 (C22), 2.4819 (C276), 2.4856 (alloy 625), 2.4858 (alloy 825)

Non-destructive testing

We are authorised to check for superficial flaws in welds and components by means of non-destructive testing.

Our personnel is certified to perform inspections in the following areas:

- Visual Testing (VT 2) and Dye Penetration Testing (PT 2)

If required or requested, we can commission an external testing body to apply testing procedures such as: - Ultrasonic Testing (UT) and/or Radiographic Testing (RT)

to find any potential defects in the material.